Plasma Treatment Homepage copy

Plasma Treatment

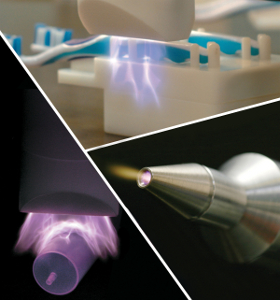

Plasma Surface Treatment & Oxygen Plasma Treatment

Plasma Treatment

Surface tension is invisible to the naked eye, but it can seriously impact an object’s function. Low surface energy or contaminants can prevent the bonding of inks and adhesives, limiting the material’s range of use. That’s why industries in plastics, metal and other fields use plasma treatments for etching, cleaning and activating surfaces.

Atmospheric plasma surface treatments are available in a variety of configurations:

- Oxygen plasma treatment

- Flame plasma treatment

- Variable chemical plasma treatment

Types of Plasma Treatment

Oxygen plasma treatment, also called corona, air treatment, or O2 treament is used in plastic film, extrusion and converting. It is important that materials are treated when they are first produced. While this treatment is required for future converting it also has a limited shelf life and an additional bump treatment is usually needed at the time of printing, coating, laminating or bonding.

Atmospheric plasma treatment is similar to oxygen plasma treatment, and is often used to a micro-etch effect on plastic surfaces including folding glue flaps in cartons. This can be integrated with production lines using open air jets.

Learn More About Plasma Treatment

We strive to provide the most accurate and up to date information on plasma treating. Our information comes from experts in the industry, unlike some resource sites, such as Wikipedia entries…so as you explore our site further, you can rest assured that information you find on plasma surface treatment is expert advice! And, we’ll continue to post the latest research information on methane, argon and nitrogen plasma treatment chemistries.

Discover more about chemical and flame plasma treatments, and you’ll learn the benefits of one surface treatment versus another. You can also watch a video demonstration of plasma treating on toothbrushes or learn more about plasma treatment of polymers.