Did you know?

Plasma Surface Treatment

If you’ve ever watched ink rub off a printed surface, witnessed the failure of an adhesive to hold two surfaces together, or observed inconsistency in the application of a coating then you’ve seen evidence of low surface energy at work. Low surface energy can be inherent in a surface or the surface can have contaminants […]

Read more...

Did you know?

Improve Adhesive Bonding with Plasma Treating

Manufacturers rely on in-line atmospheric plasma treatment to improve bonding of adhesives on plastics, metals, composites, and glass surfaces. Plasma pretreatment cleans surfaces by removing contaminants. The process also etches surfaces creating more bonding sites to facilitate stronger bonds and air plasma’s ability to functionalize surfaces activates their receptiveness to adhering with all types of […]

Read more...

Did you know?

Plasma & Flame Treating Improve Ink Jet Printing Adhesion

Did you know it’s possible ink jet print on all types of plastic surfaces? Ink jet is popular because it is a digital technology that offers many production advantages. However in some cases surfaces are not receptive to ink adhesion. This is because of low surface energy and surface contamination. To improve surface adhesion companies […]

Read more...Plasma Treatment

Plasma Surface Treatment & Oxygen Plasma Treatment

Plasma Treatment

Surface tension is invisible to the naked eye, but it can seriously impact an object’s function. Low surface energy or contaminants can prevent the bonding of inks and adhesives, limiting the material’s range of use. That’s why industries in plastics, metal and other fields use plasma treatments for etching, cleaning and activating surfaces.

Atmospheric plasma surface treatments are available in a variety of configurations:

- Oxygen plasma treatment

- Flame plasma treatment

- Variable chemical plasma treatment

Types of Plasma Treatment

Oxygen plasma treatment, also called corona, air treatment, or O2 treament is used in plastic film, extrusion and converting. It is important that materials are treated when they are first produced. While this treatment is required for future converting it also has a limited shelf life and an additional bump treatment is usually needed at the time of printing, coating, laminating or bonding.

Atmospheric plasma treatment is similar to oxygen plasma treatment, and is often used to a micro-etch effect on plastic surfaces including folding glue flaps in cartons. This can be integrated with production lines using open air jets.

Learn More About Plasma Treatment

We strive to provide the most accurate and up to date information on plasma treating. Our information comes from experts in the industry, unlike some resource sites, such as Wikipedia entries…so as you explore our site further, you can rest assured that information you find on plasma surface treatment is expert advice! And, we’ll continue to post the latest research information on methane, argon and nitrogen plasma treatment chemistries.

Discover more about chemical and flame plasma treatments, and you’ll learn the benefits of one surface treatment versus another. You can also watch a video demonstration of plasma treating on toothbrushes or learn more about plasma treatment of polymers.

Plasma Treating Facilitates Surface Performance

How can you determine if surface treatment provides the results you desire? Ideally you could integrate a plasma treating solution into your production line and see if the results meet your quality control standards. In most cases this is not practical, so laboratory treatment trials are your next best option.

In addition there are several off-line tests that you can do as part of your technology evaluation and on-going quality control processes. Developing your own specific protocols is the best way to determine if plasma treating produces the results you require.

From simple dyne level tests to advanced scientific analysis there are numerous ways to evaluate surface performance. Developing your own specific protocols is the best way to determine if plasma treating produces the results you require.

Field Applications

Plasma treatment is used across a wide variety of industries to clean, etch and functionalize surfaces. Visit our on-line library of applications and industry specific technical papers to see how atmospheric plasma is used in your industry.

OBJECT TREATING APPLICATIONS

- Adhesives

- Assembly

- Automotive

- Construction

- Electronics

- Electrical Potting

- Folding Carton

- Labeling

- Medical

- Optics

- Packaging

- Photovoltaics

- Pipes

- Plastics

- Printing

- Window & Door

- Wire & Cable

Plasma Technologies

Air Plasma Surface Treatment

Air Plasma Surface Treatment

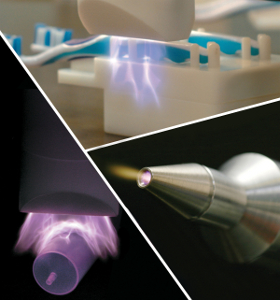

Air plasma surface treaters use either blown ion or blown arc discharge technology. A key difference between the two atmospheric plasma systems is that blown ion treatment is effective with both conductive and non-conductive surfaces.

Read more... Variable Chemistry Atmospheric Plasma Surface Treatment

Variable Chemistry Atmospheric Plasma Surface Treatment

The ability to produce long lasting treatment results on materials that would be otherwise unresponsive is one of the major advantages of variable chemistry atmospheric plasma.

Read more... Flame Plasma Surface Treatment

Flame Plasma Surface Treatment

A plasma field is formed when flammable gas and air are combined and combusted to form an intense blue flame.

Read more...New Plasma Treating eBook

A new interactive ebook is now available to that covers all the basics you need to get started with atmospheric plasma surface treatment. The 84 page on-line book uses photos, animations, and videos to help you gain a better understanding of the capabilities of atmospheric plasma treatment systems. Learn why inert plastic, metal & glass surfaces will […]

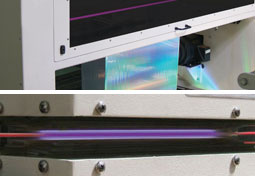

Read more...New Plasma4™ Treatment for Webs

A new atmospheric plasma technology for the surface treatment of webs has been introduced at the K Show. In addition to providing superior treatment to corona treatment systems the new Plasma4™ design promises significant performance and operating breakthroughs. It features the industry’s most efficient use of gas chemistry’s to clean, etch and functionalize surfaces. By reducing […]

Read more...Plasma Treated Materials

Plasma treating is effective at treating a wide range of polymers, elastomers, glass, metals, rubber, foams, non wovens and other composite Pretreatment of extruded, pultruded, molded, thermoformed and thermoset plastics.

Read more...Plasma Treatment Applications

In-line plasma treatment improves adhesion for a variety of plasma treatment applications. It increases productivity by eliminating the need for batch processes and eliminates the need for costly and sometimes hazardous chemical primers.

Read more...Improve Adhesive Bonding with Plasma Treating

Manufacturers rely on in-line atmospheric plasma treatment to improve bonding of adhesives on plastics, metals, composites, and glass surfaces. Plasma pretreatment cleans surfaces by removing contaminants. The process also etches surfaces creating more bonding sites to facilitate stronger bonds and air plasma’s ability to functionalize surfaces activates their receptiveness to adhering with all types of […]

Read more...Plasma & Flame Treating Improve Ink Jet Printing Adhesion

Did you know it’s possible ink jet print on all types of plastic surfaces? Ink jet is popular because it is a digital technology that offers many production advantages. However in some cases surfaces are not receptive to ink adhesion. This is because of low surface energy and surface contamination. To improve surface adhesion companies […]

Read more...