Variable Chemistry Atmospheric Plasma Surface Treatment

Dec 12th, 2008 | By kmaier@enerconmail.com | Category: Plasma Technologies, Variable Chemistry Atmospheric Plasma The ability to produce long lasting treatment results on materials that would be otherwise unresponsive is one of the major advantages of variable chemistry atmospheric plasma. However the ability to clean, etch and functionalize surfaces has made variable chemistry atmospheric plasma a breakthrough solution for many industry leading firms.

The ability to produce long lasting treatment results on materials that would be otherwise unresponsive is one of the major advantages of variable chemistry atmospheric plasma. However the ability to clean, etch and functionalize surfaces has made variable chemistry atmospheric plasma a breakthrough solution for many industry leading firms.

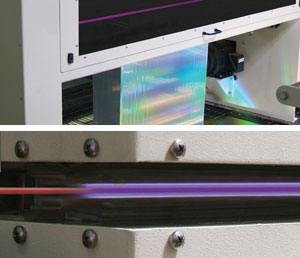

Powerful yet gentle Variable Chemistry Atmospheric Plasma treaters are ideal for delicate surfaces. These advanced systems are ideal for hard-to-treat materials and plasma delivery systems can be configured to treat virtually any surface.

Variable chemistry atmospheric plasma is formed using basic principles found in air plasma and flame plasma treatment. A chemistry plasma field is generated in an electrically charged atmosphere. The introduction of gas chemistries at a controlled power level to a proprietary electrode produces a high density glow discharge that creates high surface energy. Low molecular weight materials such as water, absorbed gases and polymer fragments are knocked off the surface to expose a clean, fresh surface. At the same time a percentage of the reactive components in plasma with sufficient energy bond to the freshly exposed surface, changing the chemistry of the surface and imparting the desired functionalities.

To compare the advantages and application considerations, request a copy of the plasma treatment technology comparison chart.